Main products

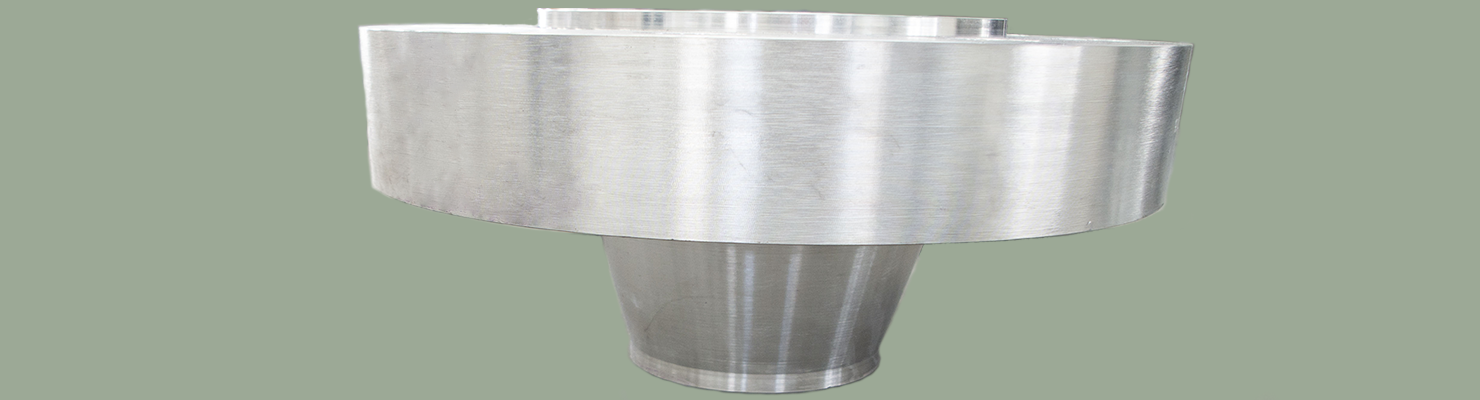

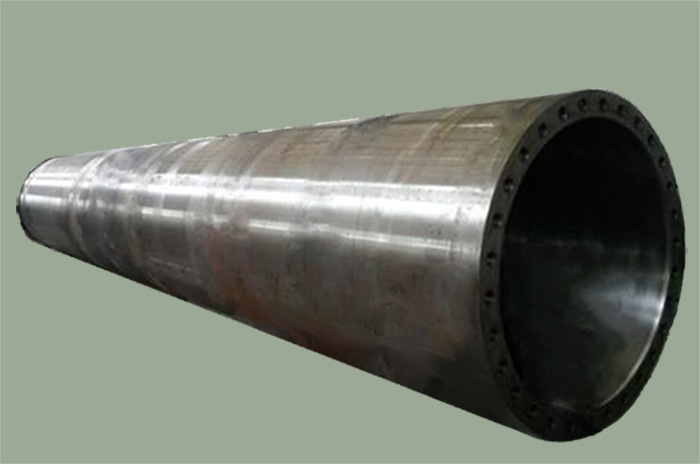

Free Forging:we can manufacture as your drawings.

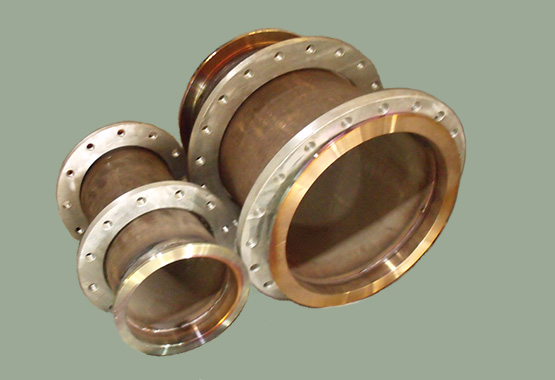

Hydraulic Cylinder

ABOUT COMWELL METAL CO., LTD

Committed to providing the best Products in Shenzhen China

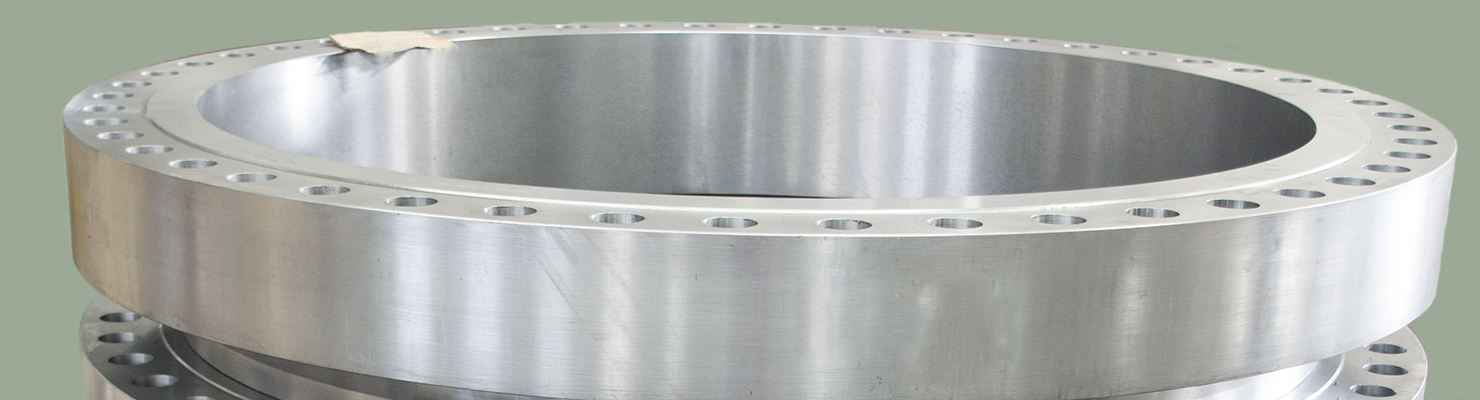

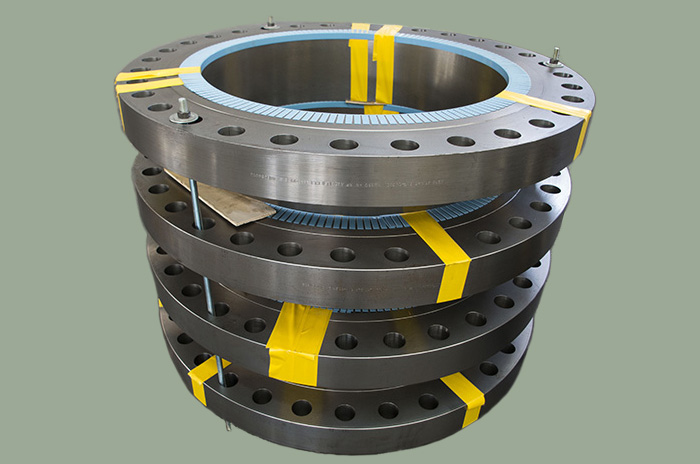

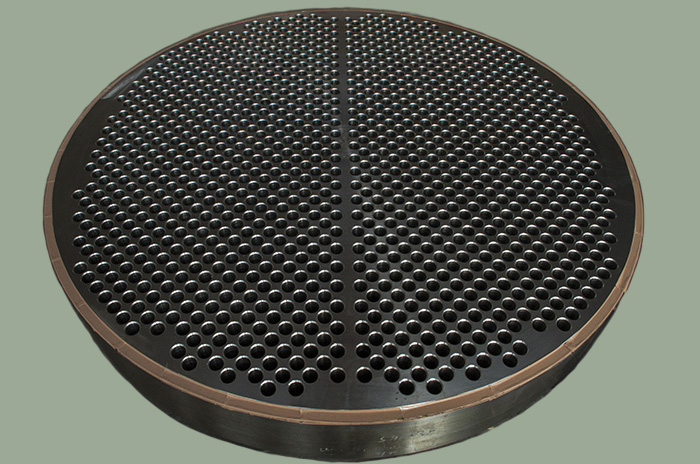

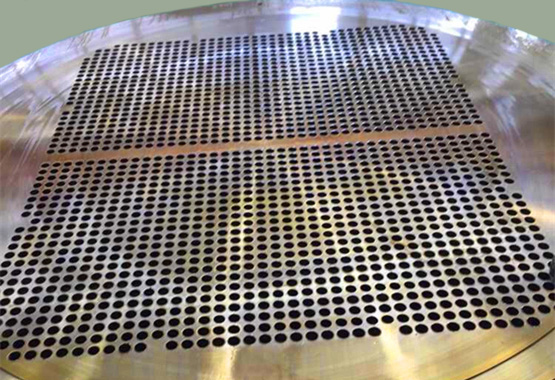

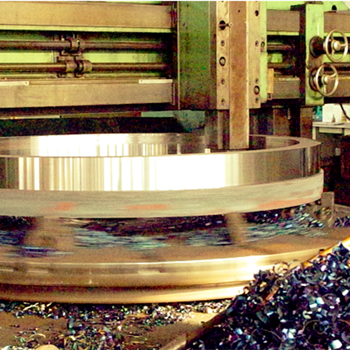

Comwell metal co.,ltd is mainly engaged in heat-treating, forging, machining(Turning, Milling, Planing, Grinding, Drilling) with kinds of non-standard forgings and standard forgings of material: Carbon Steel, Alloy Steel, Low Temperature Carbon Steel, Stainless Steel and Cupronickel. Our main products: Tube Sheet, Forging Ring, Forging Blind, Forging Flange, Shaft, Hydraulic Cylinder. Which can be used to kinds of Pressure Vessels, Petroleum, Chemical, Hydropower, Nuclear Power, Shipbuilding, Pharmacy, Metallurgy, Refrigeration, Food, Production Facility. Our products exported to Europe, Mid-east, Algeria, South Africa, Canada, American, Brazil, New Zealand, Australia, Southeast Asia.

In addition to offering top quality products ,our factory employs qualified engineers, capable of advising and assessing customer’s individual needs. you will find that we are highly flexible and willing to adapt our processes to meet the needs of every one of our customers.

we aim to provide the highest product quality and best customer service.

Equipment & Machining

Our factory have a variety of domestic and international standards

Main machining & processing equipments:

CNC boring and milling center

Vertical lathe:φ3500

Heavy duty horizontal lathe:φ1.8×8M

Heavy duty deephole drilling and boring machines:Especially suitable for large pieces with inner-hole and with eccentric hole rough processing

Main forging equipment:

Oil hydraulic press: 3150T,800T

Flat-die hammer: 5T

CNC grinding ring equipment:6000mm,2800mm

Min heat treatment equipments:

we use resistance-heated furnace: the workpiece is uniformly heated and accurate, high quality, small deformation.

well type quenching and tempering furnace:φ5.5×2M ,φ3.5×4M

well-type carburizing furnace:φ1.6×8M,φ2.0×2M

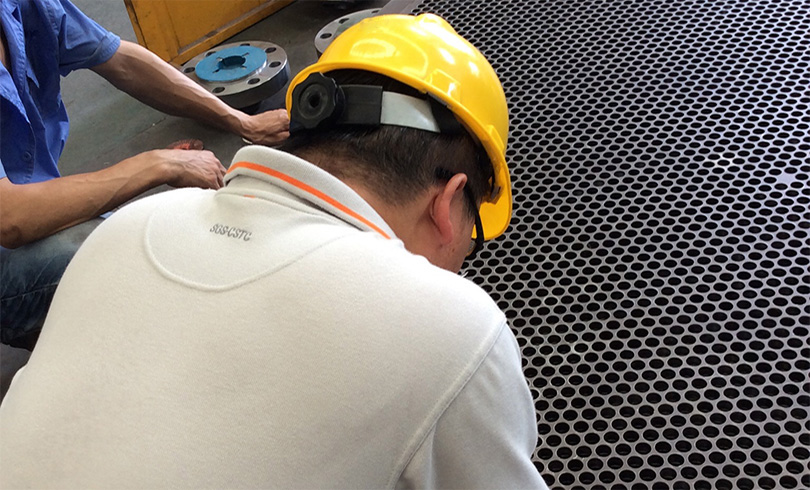

Inspection

All products have to pass strict inspection before they go out.

We always have been serious about our products and respect the special requirements of customers. From heat treatment to the products be packaged and dispatched, We have strict inspection and testing. Each forging products must pass the UT test, Meanwhile our inspector will measuring the machining size time to time. All the measuring tools we use are calibrated according to required. For the forged parts with large and with high precision, We will provide SGS test report to our customer, Customer also can specify the detection mechanism to detect our products according to their own needs.